Product Description

MCH1 9.5" Carbon Fiber Injector Hat DMPE 400-043-99-1488A

This hat currently only works with our M6 blower set up. We are designing a new adapter plate that will allow this to be run on any blower with a standard opening. We will update this page with more information once we have the adapter ready.

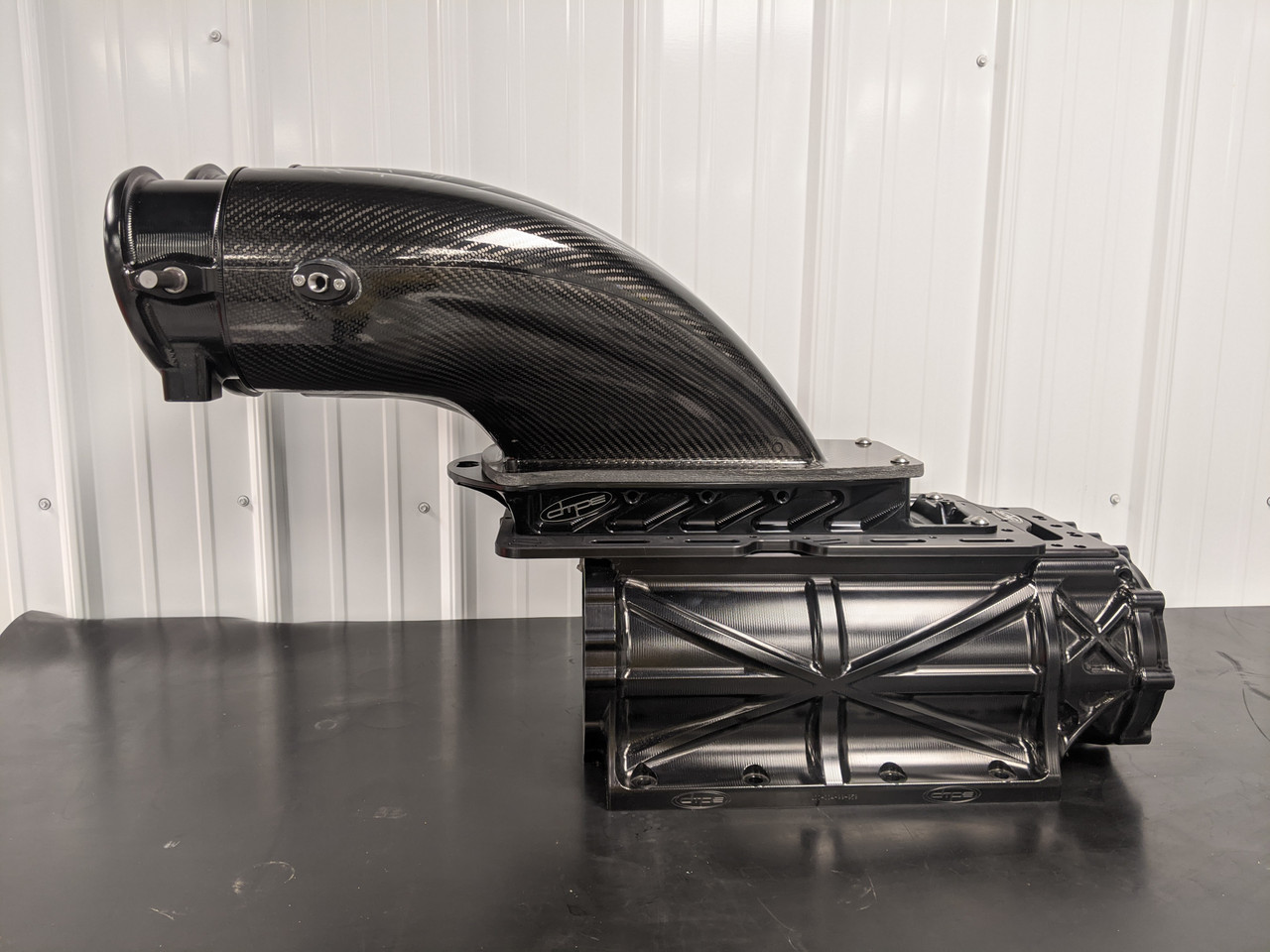

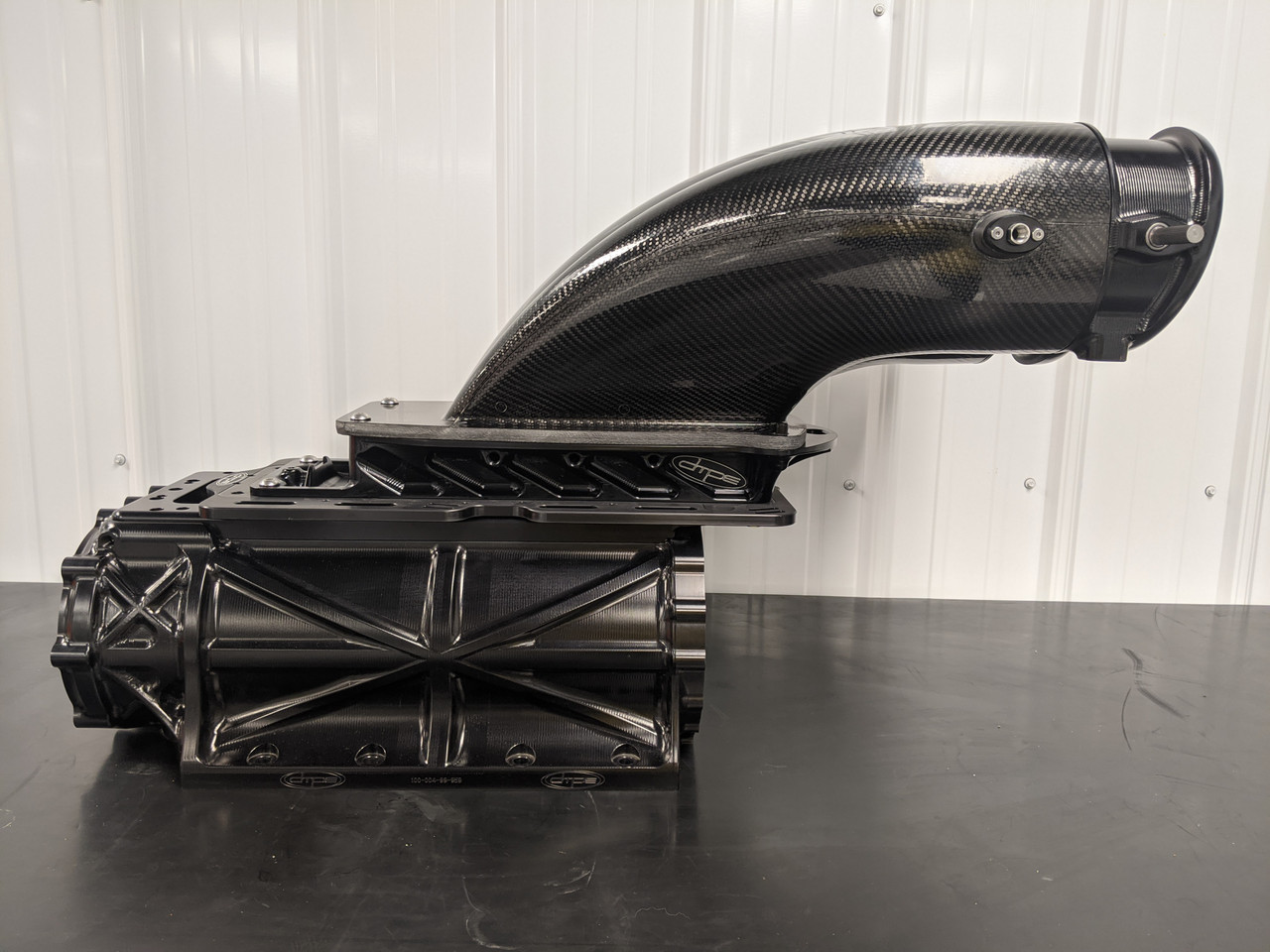

The next generation of DMPE Roots injector hat comes to completion. We started from scratch again with the intentions of going to the next level with design and manufacturing principles on our new injector. The hat is 3D designed and machined in-house using our new DMG DMU 95 5 axis machining center. The carbon work was moved from a small carbon shop in England back to our home state of Michigan to Roush industries. Roush, known for its state of the art quality and equipment in the composite world. It really shows with the strength of the carbon bodies. Its literally twice as strong as our previous carbon parts. We moved away from a molded throttle body area to a billet 5 axis machined throttle body. This allows for a perfectly shaped throttle blade bore. This was a struggle with the carbon bores as we spent lots of time fitting the blades perfectly. The throttle blades previous, as all typical blades do, flexed under idle vacuum and made setting the idle on the modern large blade area hats a challenge. In many cases we had to use Titanium to help solve the issue. We definitely wanted this solved in the new design. The new blades slide over the stainless shaft, rather than through a slotted shaft. This solved the flexing issue. We went even further with strengthening the blades by contouring the blades to increase their surface area while reducing the weight. The front of the blade is a fresh, clean design and the rear of the blade is shaped for strength. The DJE Impact nozzle's are also available in a modular spray bar option. Provisions are provided in the design to add a spray bar at any time or run it without. This way there are no extra labor costs if you choose to add a spray bar later. Remove the caps, slide in the bar, and tighten the screws, done. A variety of colors are available for blades and throttle bodies if a customer should choose at time of ordering. Because of the modern manufacturing principles, equipment, software, and Roush on the carbon side, we have been able to bring to market the top shelf part at a competitive price.

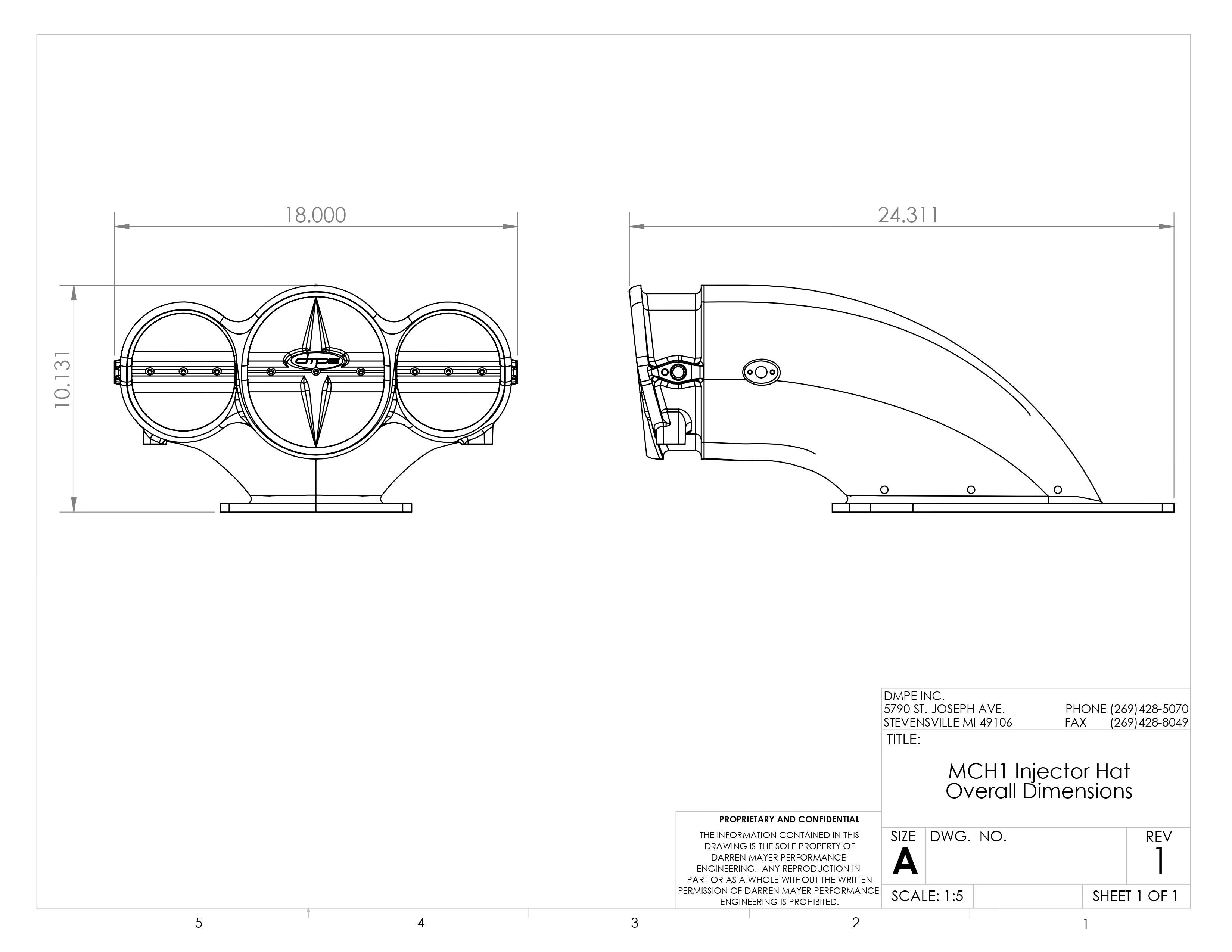

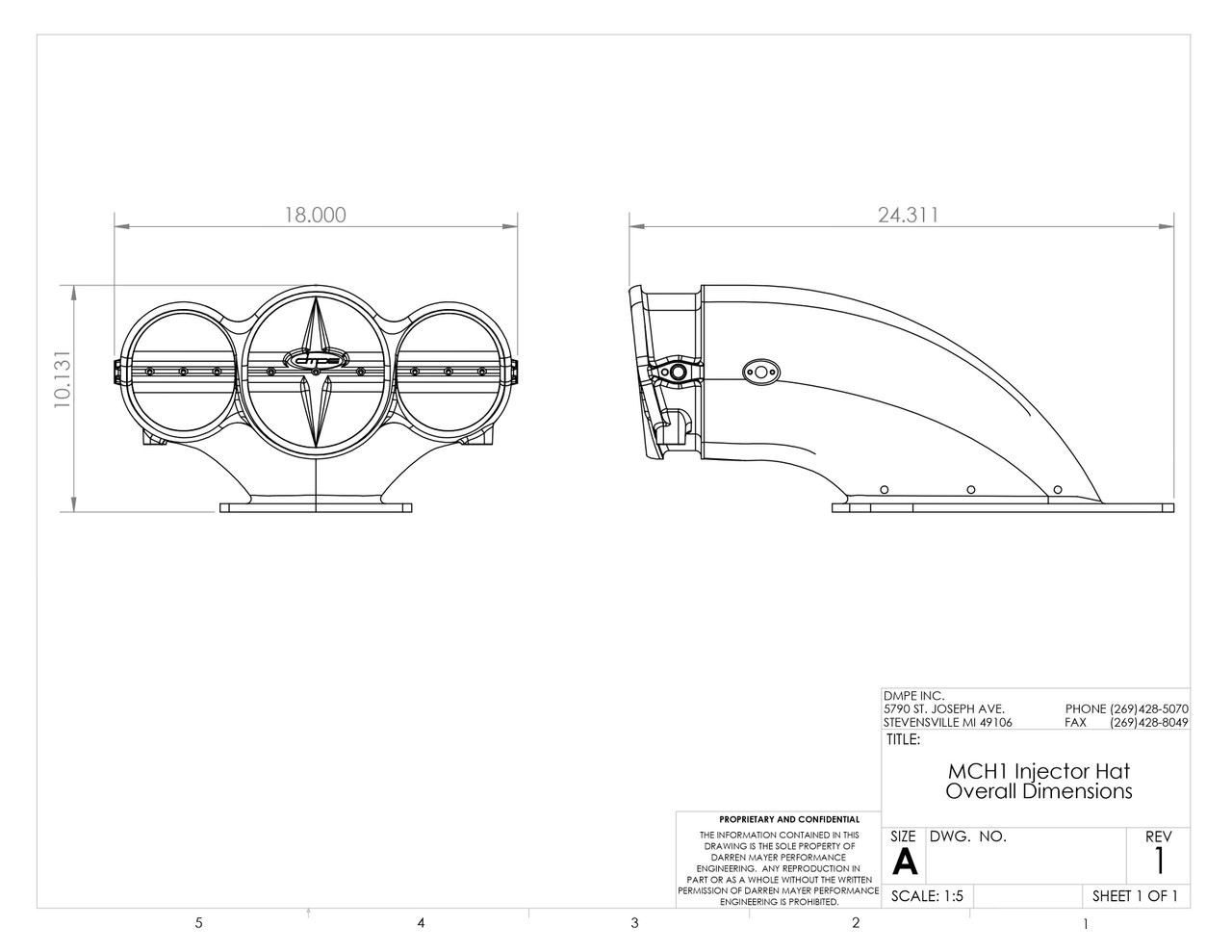

DMPE MCH1 Injector Hat Dimensions